BOMBAY PHARMA EQUIPMENTSP.LTD

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to BOMBAY PHARMA EQUIPMENTSP.LTD

Bowl Lifting Device

- EASY TO OPERATE AND CLEAN

- TOTALLY CLOSED OPERATION TO AVOID DUSTING

- EASY FOR CONTINUOUS DISCHARGE

- EASY TO CLAMP WITH FLUID BED DRYER BOWL

- MOC SS 304 / 316

- HYDRAULIC POWER PACK ARRANGEMENT FOR SMOOTH JERK FREE LIFTING

- TROUBLE FREE TILTING ARRANGEMENT

- STRUDY UNIT WITH S.S. CONSTRUCTION

- CGMP MODEL WITH DOCUMENTATION (IQ, DQ, PQ, OQ) - AS OPTION

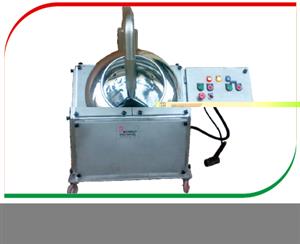

Coating Pan

- SUITABLE FOR COATING OF TABLETS & CONFECTIONERIES

- (SUGAR / FILM COAT)

- MODELS AVAILABLE FROM 12" TO 72"

- SUITABLE EXHAUST BLOWER AVAILABLE HEATERS & BLOWER MOTOR IS ELECTRICALLY INTERLOCKED

- MOC S.S. 304 / 316 / 316L

- ANGLE INCLINATION OF 45 AND CAN BE ADJUSTED AS PRE REQUIREMENT

- DRIVE UNIT WITH REDUCTION GEAR BOX PROVIDED

- S.S. STRUCTURE WITH ADEQUATE OPENING FOR EASY MAINTENANCE

- CGMP MODEL WITH DOCUMENTATION (IQ, DQ, PQ, OQ)- AS OPTION

Double Cone Blender

- EFFICIENT & VERSATILE MIXER.

- IDEAL FOR MIXING POWDERS AND HOMOGENEOUS LUBRICATION OF GRANULES

- MOC S.S. 304 / 316 / 316 L

- S.S. BAFFLES ARE PROVIDED

- SAFETY GUARDS PROVIDED WITH LIMIT SWITCH INTERLOCKED TO MOTOR

- CAPACITY 20 LTRS. TO 2500 LTRS.

- AUTOMATIC LOADING & UNLOADING FACILITIES AVAILABLE (OPTION)

- CGMP MODEL WITH DOCUMENTATION (IQ, DQ, PQ, OQ) - AS OPTION

Dry Powder Filling Machine

This machine is ideal for dry powder and external dry syrup filling. The design is unique & extremely functional. The machine is simple to operate, readily movable and occupies minimal space. This machine gives OPTIMUM PRODUCTION WITH MINIMUM WEIGHT VARIATION.

[DRY POWDER FILLING MACHINE]

Dry Powder Filling Machines

SALIENT FEATURES :

• Easy to maintain and simple to operate.

• Automatic Powder level maintaining system for maintaining constant level of powder to facilitate minimum weight variation.

• Minimum space requirement.

• Present revolution control with digital display for quick setting of fill weight.

• No mechanical settings, hence can be set & operated by unskilled operator.

• Instant Brake mechanism for precise fill weight.

• Weight variation within + 2%

• Table model - compact & easily movable from place to place.

• Versatile, can handle dry syrup powder filling.

• Quick interchangeability in minutes for changeover of product.

• All powder contact parts are made of stainless steel 316 or non contact parts are made from stainless steel 304 quality as

per customer's requirement.

Starch Paste Kettle

SALIENT FEATURES :

• It is Specially Designed for Preparation of Binder Material.

• Hemispherical Kettle with Jacket Mounted on Trunion Supports with the Help of Shaft.

• The Kettle has a Small Cylndrical top Shell With a Spout for Pouring out Binder Mass.

• Jacket is Provided with Steam Accessories, Pressure Gauge , Safety Valve and Vent Cock.

• The Kettle is also Provided with a Lever with Hand Wheel to Accomplish Tilting Manually.

• The Kettle is Provided with 16 Swg Thick S.S.304 Loses Lid.

Fluid Bed Dryer

- VERY VERSATILE PROCESS EQUIPMENT FOR UNIFORM AND EFFICIENT DRYING OF PRODUCTS.

- FULLY AUTOMATIC OPERATION BASED ON PLC CONTROL

- / WITHOUT PLC CONTROL

- MINIMUM HANDLING AND MORE HYGIENIC

- LIFTING & TILTING DEVICE OF PRODUCT CONTAINER FOR EASY HANDLING

- CAPACITY AVAILABLE FROM 5 Kgs to 500 Kgs.

- FLP MODELS AVAILABLE AS OPTION

- MOC S.S. 304/ 316/ 316L

- OPTION - STEAM HEATED OR ELECTRIC HEATED BLOWER

- CGMP MODEL WITH DOCUMENTATION (IQ, DQ, PQ, OQ) - AS OPTION.

Mass Mixer

- SUITABLE FOR MIXING WET AND DRY POWDERS

- PADDLE TYPE BLADES

- PROVIDED WITH LEAK PROOF SEAL TILTING ARRANGEMENT, LIMIT SWITCH WITH S.S. GRILL

- S.S. 304 / 316 QUALITY AND MIRROR POLISHED UNIT WITH SUITABLE MOTOR AND GEAR BOX

- MANUAL TILTING ARRANGEMENT MODEL 25, 50, 100, 200 & 250 Kgs.

- CGMP MODEL WITH DOCUMENTATION (IQ, DQ, PQ, OQ) - AS OPTION

Multi Mill

- SUITABLE FOR DRY GRANULATION / PULVERISING / SHREDDING & CHOPPING OF MATERIALS

- MULTI SPEED DRIVE FOR VARIOUS PRODUCT GRADING

- EASY DISMANTLING AND CLEANING

- OUTPUT 100 TO 250 Kgs/hr DEPEND UPON CHARACTERISTIC OF PRODUCT & THE SCREEN SIZE

- EASY MANOUEVARABILITY WITH THE HELP OF CASTOR WHEELS

- MOC S.S. 304 / 316 / 316 L

- MOTOR - 3 HP / 1440 RPM, ROTOR DIA - 250 MM APPROX

- BEATERS - 12 NOS WITH KNIFE/ IMPACT EDGE AND 2 SCRAPPER BLADES.

- ROTOR SPEED - 720 / 1500 / 2100 / 3000 RPM APPROX

- OVERALL DIA - 900 L x 800 W x 1700H (IN MM)

- CGMP MODEL WITH DOCUMENTATION (IQ, DQ, PQ, OQ) - AS OPTION

Octagonal Blender

- SUITABLE FOR QUICK AND EFFICIENT MIXING FOR A COMPLETE RANGE OF POWDERS, PARTICULATE AND GRANULAR MATERIALS.

- HOMOGENEOUS MIX. GENTLE TUMBLING ACTION WITH A SPECIALLY DESIGNED BAFFLE.

- EASY CHARGING OF MATERIALS THROUGH S.S. BINS.

- CAPACITY - 20 LTRS. TO 4000 LTRS.

- MOC - S.S. 304/ 316/ 316 L

- SHAPE OF CONTAINER - POLYGON SHAPED FRUSTUM.

- S.S. OCTAGON TYPE BODY WITH RECTANGULAR CENTRAL PORTION TOP AND CIRCULAR BOTTOM WITH A BUTTERFLY VALVE.

- CGMP MODEL WITH DOCUMENTATION (IQ, DQ, PQ, OQ) - AS OPTION

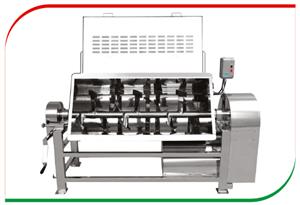

Oscillating Granulator

- STANDARD MODEL, HOPPER CAPACITY 34 LTRS. THE BODY OF THE MACHINE IS "L" SHAPED STRUCTURE SCREEN AREA 12.6" x 14.5"

- DRUM SIZE 5.4" DIA x 14.4" LENGTH

- OUTPUT 30 TO 200 Kgs/hr (APP. FOR DAMP. MATERIALS)

- 200 TO 500 Kgs/hr (APP FOR DRY MATERIALS) OUTPUT DEPENDS ON THE CHARACTERISTIC OF PARTICLE PRODUCT AND THE REDUCTIONS REQUIRED IN SIZE.

- POWER SUPPLY - 2HP, 1440 RPM 440 VOLTS 3 PHASE 50 CYCLES A.C. NET WEIGHT 250 Kgs. APPROX

- GROSS WEIGH 400 Kgs APPROX

- OVERALL DIMENSION - 32" x 18" x 49" (H)

- COMPACT & STURDY UNIT

- CGMP MODEL WITH DOCUMENTATION (IQ, DQ, PQ, OQ) - AS OPTION

Rapid Mixer Granulator

- CAPACITY 25 LTRS TO 1000 LTRS

- DUAL SPEED IMPELLER AND CHOPPER

- SUITABLE FOR EFFICIENT & FAST MIXING OF GRANULATION

- OF INGREDIENTS

- MATERIAL HANDLING SYSTEM IS PROVIDED FOR LOADING

- OF MATERIAL

- CIP SYSTEM WILL BE PROVIDED WITH PUMP AS OPTIONAL

- M.O.C. S.S. 304/316/316L

- CONSISTANT QUALITY IN EACH BATCH

- FULLY HYGIENIC MIXING.

- OPTION - ARRANGEMENT FOR BINDING SPRAY

- MACHINE WITH PLC SYSTEM AS AN OPTIONAL

- CGMP MODEL WITH DOCUMENTATION (IQ, DQ, PQ, OQ) - AS OPTION

Liquid Or Syrup Manufacturing Plant

SALIENT FEATURES :

• The Automatic Liquid manufacturing plant is designed to be operated only by one operator and one helper.

• All material transfers are done by Vacuum or by Transfer Pumps.

• All the Vessels are CGMP (Paint free Construction).

• The Gaskets used are of Silicon (Food Grade).

• All Contact parts are of S.S. 316 Quality material (SS304 provided on demand) & Finished to mirror finish and crevice free.

• The entry of Stirrer & High Speed Emulsifier are from top. In-Line Emulsifier (As per customer choice) provided on Demand. (Optional in Liquid Manufacturing Plant).

• All Vessels are suitable for internal pressure of 1 KG. / SQ. CM. and Hence can be Sterilized.

• All Pipes, Pipe Fittings and Valves are of SS316 / Ss304 (As per customer requirement) Seamless Quality, Internally Electro Polished, with Tri-Clover Ended Joints.

• Transfer pumps provided to Transfer ready product to filling line.

• The Entire plant is Equipped with CIP & SIP Connection, so that customer can us this facility, If have CIP & SIP Equipment.

• All Values of temperature & time of the plant are indicated digitally on the Controal Panel. Ampere indicates on Ampere Meters. (Automatic Liquid manufacturing Plant).

• A Micro processor Based Automatic operating Liquid Manufacturing Plant can be Designed as per Requirement (Optional).

• All the Inlet & Outlet connections are provided with Tri Clover joints, which are very easy for cleaning & Replacement.

Vibro Sifter

- IDEAL FOR GRADATION & SEPARATION OF DRY POWDER, GRANULES AND SEMI SOLIDS / LIQUIDS.

- MODELS 20", 30", 36", & 48"

- MODULAR DESIGN OF DECKS WITH EASILY FITTED CLAMPS

- SUITABLE FOR WIDEST RANGE OF MATERIAL

- LESS POWER CONSUMPTION, VARIABLE FLOW PATTERN

- DUST FREE ARRANGEMENT, LEAD FREE SIEVES

- EASY DISMANTLING AND CLEANING

- OUTPUT 80 TO 200 Kgs/hr DEPEND UPON CHARACTERISTIC OF MATERIAL

- M.O.C.S.S. 304/316/316L

- RUBBER MOULDED SIEVE AS OPTIONAL

- BALL TRAY ARRANGEMENT (FOR CHOCKING OF SIEVES)

- FREED TRAY ARRANGEMENT (FOR SMOOTH FLOW OF MATERIALS)

- CGMP MODEL WITH DOCUMENTATION

- (IQ, DQ, PQ, OQ) - AS OPTION

Zero Hold Up Filter Press

“BOMBAY PHARMA EQUIPMENTS PVT.LTD.” has been actively involved in the manufacturing of filtration system more than Fifteen years. We are now adding one more our best product “Zero Hold Up Filter Press” to our range of Product.

REVERSE FLOW ZERO HOLD UP TYPE : Here the direction of flow of liquid is exactly opposite to the flow in standard filter i.e. the impure liquid to be filtered enters the filter from the bottom into the center channel & goes to the top of each plate. The clear filtrate flows out from openings on side of plates to the shell & then to the outlet. This flow ensure almost 100% filtration of the liquid which is not so with the standard flow type.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.